Share:

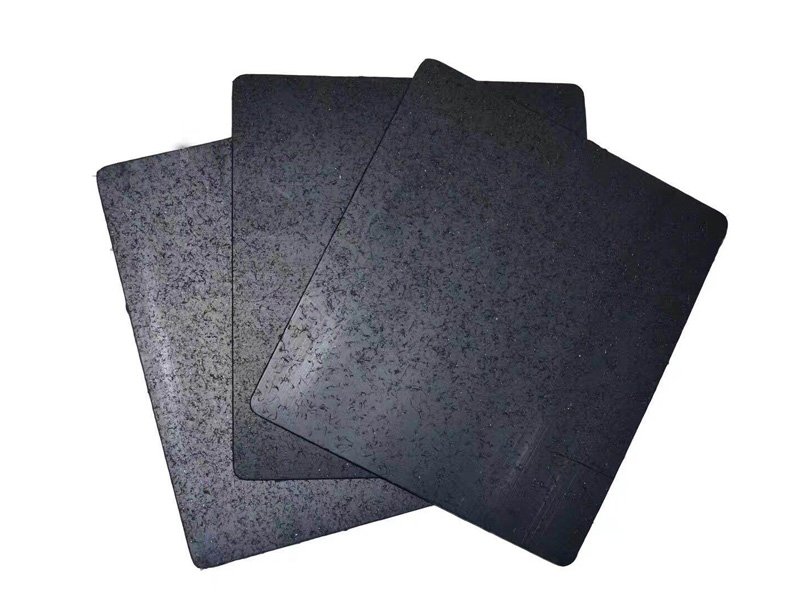

Textured geomembrane is synthetic barriers designed to create a strong seal against fluid or gas migration in civil, geotechnical, and environmental engineering applications. Unlike smooth geomembranes, textured versions feature an embossed surface that enhances frictional characteristics, crucial for improving slope stability and preventing slippage in applications such as landfill liners and containment structures.

These geomembranes are essential in modern engineering, offering exceptional stability, durability, and impermeability across various uses. From landfill liners to aquaculture ponds, their unique surface ensures safety and performance in challenging environments. Understanding their features and benefits allows for informed decision-making to optimize project success.

Whether for large mining operations or small agricultural ponds, textured geomembranes provide a reliable, cost-effective solution. At BPM Geosynthetics, we offer high-quality textured geomembranes at competitive factory prices, ensuring you receive the best value for your projects.

A textured geomembrane is a high-performance, synthetic membrane typically made from high-density polyethylene (HDPE) or linear low-density polyethylene (LLDPE), engineered with a rough surface on one or both sides. Unlike smooth geomembranes, the textured surface of a textured geomembrane enhances friction, making it ideal for applications where stability on slopes or uneven terrain is critical. The texture is created through advanced manufacturing processes like co-extrusion or calendaring, which introduce patterns such as studs or asperities to increase grip.

Textured geomembranes are designed to serve as impermeable barriers, preventing the migration of liquids, gases, or contaminants in various engineering projects. Their unique surface texture distinguishes them from smooth counterparts, offering superior performance in challenging environments like landfills, mining operations, and water containment systems. By combining impermeability with enhanced frictional properties, textured geomembranes ensure both safety and longevity in demanding applications.

Item | Specification | |||||

The resin thickness of middle fabric mm > | h | l | p | g | gl | |

0.40 | ||||||

Tension | Maximum tension N/cm > | 120 | 250 | 120 | ||

Tension strength MPa > | 10 | 10 | ||||

Maximum tension elongation %> | 15 | |||||

Fracture elongation %> | 200 | 150 | 200 | 100 | ||

Heat treatment size change rate %≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

Low-temperature bending | No craze -25℃ | |||||

Water tightness | No seepage 0.3 Mpa, 2h | |||||

One of the primary functions of a PVC geomembrane is its ability to prevent water migration. The impermeability of PVC makes it an excellent choice for applications that require effective containment of liquids.

PVC geomembranes are designed to last, with a lifespan of up to 20 years when properly installed and maintained. They are resistant to weathering, UV radiation, and environmental stressors, ensuring long-term performance.

PVC geomembranes exhibit good resistance to a wide range of chemicals, including acids, alkalis, and salts. This property makes them suitable for various industrial applications where chemical exposure is a concern.

The inherent flexibility of PVC geomembranes allows for easy installation over uneven surfaces. This adaptability is essential in applications such as landfill sites and irrigation ponds.

PVC geomembranes are generally more affordable than other geomembrane options, such as HDPE (High-Density Polyethylene). This cost efficiency makes them a preferred choice for many projects.

The lightweight nature of PVC geomembranes simplifies transportation and installation. Additionally, they can be welded together using heat or solvent methods, ensuring secure seams.

Formulated with UV stabilizers, it retains 85% integrity after 1,000 UV hours (ASTM G154), performing reliably in sunny climates.

PVC geomembranes can be used in a wide range of applications, including:

Both materials have environmental considerations, but PVC geomembranes can be recycled, providing an eco-friendly option at the end of their life cycle.

No | Feature | PVC Geomembrane | HDPE Geomembrane |

1 | Flexibility | High – conforms to irregular surfaces | Moderate – less flexible |

2 | Chemical Resistance | Good | Excellent |

3 | UV Resistance | Moderate – requires stabilizers | High – inherently UV resistant |

4 | Installation Ease | Easier due to flexibility | More challenging due to stiffness |

5 | Cost | Generally lower | Generally higher |

6 | Typical Applications | Landfills, ponds, canals | Mining, hazardous waste containment |

Yes, a PVC geomembrane is highly effective for containment systems, offering reliable performance across applications.

Its 10⁻¹² cm/s permeability blocks 95% fluid migration, retaining leachates in landfills and water in ponds (Geosynthetics Magazine). Reinforced PVC handles 200 N tear forces, ensuring stability under waste loads.

A PVC geomembrane excels when flexibility and cost are priorities, though HDPE may be better for extreme chemical exposure.

BPM Geosynthetics is a global leader and manufacturer of geomembranes engineered specifically for your containment systems. We offer complete range of best quality geomembranes at competitive factory price on fast delivery.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

When you’re looking for geomembrane or geosynthetics products or services, we are always here repond to your quote as soon as possible.