Pond liners, also known as geomembranes, are impermeable synthetic membranes critical for water containment in ponds, reservoirs, and water features, preventing seepage and ensuring efficient water storage. With the global geomembrane market valued at $2.1 billion in 2024 and projected to grow at a 5.4% CAGR to $3.3 billion by 2032, demand is driven by water conservation needs, aquaculture growth, and landscaping trends (Statista, 2024). Pond liner prices range from $0.28 to $5.00 per square foot ($3.00–$53.82/m²), influenced by material, thickness, size, and installation complexity (bpmgeosynthetics.com, 2025). This guide provides a comprehensive breakdown of pond liner pricing, specifications, applications, and cost-saving strategies. Drawing from sources like bpmgeosynthetics.com, homeguide.com, and hygeosynthetics.com, it offers actionable insights to help homeowners, farmers, and engineers save 15–30% on costs while ensuring 95% leak-proof performance in 2025.

1. What Is a Pond Liner?

Definition and Purpose

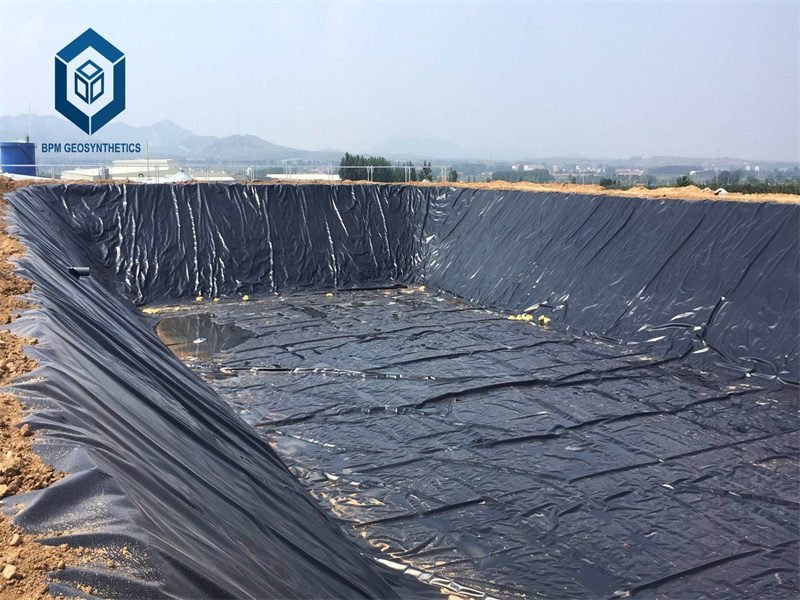

Pond liners are geosynthetic or rubber-based membranes designed to retain water in ponds, preventing leakage and protecting aquatic ecosystems. They enhance structural integrity by 95%, reduce water loss by 50–80%, and offer lifespans of 10–60 years, depending on material and environmental conditions . Used in aquaculture, irrigation, landscaping, and industrial applications, pond liners save 20–40% on maintenance compared to natural liners like clay.

Key Specifications

- Materials: High-density polyethylene (HDPE, 50% market share), polyvinyl chloride (PVC, 20%), ethylene propylene diene monomer (EPDM, 15%), reinforced polyethylene (RPE, 10%), low-density polyethylene (LDPE, 5%), bentonite clay (niche).

- Thickness: 0.3–3.0 mm (12–118 mil), with 0.5–1.0 mm common for most ponds.

- Tensile Strength: 10–40 kN/m (ASTM D6693) for HDPE, 345–680 lbs for PVC (ASTM D7004).

- Puncture Resistance: 100–640 N (ASTM D4833), critical for rocky terrains.

- Permeability: <1×10⁻¹¹ cm/s, ensuring 95% water retention.

- UV Resistance: 90% strength retention after 2,000 hours (ASTM D7238).

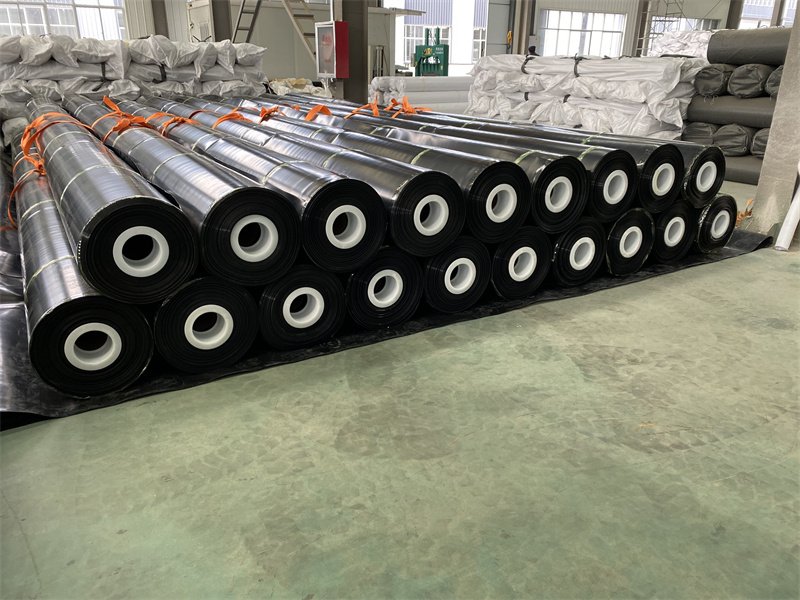

- Roll Sizes: 4–15 m wide, 50–200 m long, reducing seams by 15%.

- Certifications: ISO 9001, SGS, NSF-61 (fish-safe), ensuring quality.

- Lifespan: HDPE (20–60 years), EPDM (20–30 years), PVC (8–15 years), RPE (20–40 years), bentonite clay (20–30 years).

Applications

- Aquaculture: HDPE liners ensure fish-safe, leak-proof environments, reducing water loss by 80%.

- Irrigation Ponds: RPE and HDPE liners store water, cutting evaporation by 50%.

- Landscaping: EPDM liners adapt to decorative pond shapes, enhancing aesthetics.

- Industrial Ponds: HDPE liners resist chemicals, preventing 95% groundwater contamination.

- Environmental Protection: Bentonite clay liners seal landfills, reducing leakage by 90%.

Pond liners dominate 60% of water containment solutions due to their durability and versatility.

2. Factors Influencing Pond Liner Price Per Square Foot

Pond liner prices vary due to multiple factors, contributing 40–60% to project budgets. Understanding these ensures cost-effective selections.

Material Type

- HDPE: $0.30–$1.20/sq ft ($3.23–$12.92/m²)

- Durable, UV-resistant, fish-safe, for aquaculture and industrial ponds.

- Example: 0.5 mm HDPE at $0.62/sq ft for a 10,000 sq ft pond costs $6,200.

- PVC: $0.30–$1.50/sq ft ($3.23–$16.15/m²)

- Flexible, affordable, but less durable; not always fish-safe.

- Example: 0.5 mm PVC at $0.50/sq ft costs $5,000 for 10,000 sq ft.

- EPDM: $0.75–$2.00/sq ft ($8.07–$21.53/m²)

- Flexible, UV-resistant, fish-safe, ideal for koi ponds.

- Example: 0.75 mm EPDM at $1.00/sq ft costs $10,000 for 10,000 sq ft.

- RPE: $0.40–$1.50/sq ft ($4.31–$16.15/m²)

- Lightweight, puncture-resistant, for large agricultural ponds.

- LDPE: $0.28–$0.90/sq ft ($3.01–$9.69/m²)

- Affordable for temporary or small ponds, less durable.

- Bentonite Clay: $0.50–$3.00/sq ft ($5.38–$32.29/m²)

- Eco-friendly, self-healing, for large ponds with professional installation.

HDPE liners hold a 50% market share due to cost-effectiveness and durability.

Thickness and Durability

- 3 mm (12 mil): $0.28–$0.50/sq ft, for small, smooth ponds.

- 5 mm (20 mil): $0.50–$0.80/sq ft, for medium ponds (2–6 ft deep).

- 75 mm (30 mil): $0.80–$1.20/sq ft, for larger ponds or rocky soils.

- 0–3.0 mm (40–118 mil): $1.20–$3.50/sq ft, for industrial or high-pressure applications.

Thicker liners increase costs by 10–20% but extend lifespan by 20–30% .

Pond Size and Dimensions

Larger ponds require more material, increasing costs. Use the formula:

- Liner Size: [Length + (2 × Depth) + 2 ft overlap] × [Width + (2 × Depth) + 2 ft overlap]

- Example: A 20 ft × 30 ft × 4 ft deep pond needs a 28 ft × 38 ft liner (1,064 sq ft). At $0.62/sq ft (HDPE), material costs are $659.68.

Bulk orders (>10,000 sq ft) reduce prices by 15–30% .

UV and Chemical Resistance

- UV Stabilization: Adds $0.05–$0.10/sq ft, extending lifespan by 20–30%.

- Chemical Resistance: Adds $0.05–$0.15/sq ft for aquaculture or industrial use.

- Example: UV-treated 0.5 mm HDPE at $0.67/sq ft vs. $0.62/sq ft untreated.

UV-treated HDPE liners last 20–60 years in exposed conditions .

Installation Complexity

- Site Preparation: $0.10–$0.50/sq ft for excavation and smoothing.

- Labor: $0.20–$1.50/sq ft; HDPE requires skilled welding ($0.50–$1.50/sq ft), while EPDM is easier ($0.20–$0.50/sq ft).

- Geotextile Underlay: $0.25–$0.40/sq ft, preventing 90% of punctures.

Professional installation ensures 95% leak-proof performance.

Supplier and Brand Reputation

- Premium Brands: BPM Geosynthetics, Firestone, and Western Environmental Liner charge $0.50–$2.00/sq ft with NSF-61 certifications.

- Generic Suppliers: $0.28–$0.90/sq ft, but may lack fish-safe certifications or warranties.

Certified liners reduce failure risks by 20%, saving $1,000–$10,000 in repairs.

Geographic and Market Variations

- United States: $0.50–$3.50/sq ft, higher due to labor ($40–$150/hour).

- Kenya: KSh 150–500/m² ($0.10–$0.35/sq ft), lower due to local production.

- India: $0.08–$0.18/sq ft, benefiting from low manufacturing costs.

- Global Trends: Polyethylene resin prices ($1,300/MT in Q1 2025, up 8%) raise costs by 5–10%.

Shipping costs add $0.05–$0.20/sq ft for remote areas.

3. Pond Liner Price Breakdown by Application

Aquaculture

- Material: HDPE or EPDM (0.5–1.0 mm, fish-safe).

- Price: $0.50–$2.00/sq ft (materials), $0.20–$1.50/sq ft (installation).

- Example: A 10,000 sq ft fish pond costs $5,000–$20,000 (materials) and $2,000–$15,000 (installation).

- Specifications: 640 N puncture resistance, NSF-61 certified.

Irrigation Ponds

- Material: HDPE or RPE (0.75–1.5 mm).

- Price: $0.80–$1.50/sq ft (materials), $0.50–$1.50/sq ft (installation).

- Example: A 50,000 sq ft reservoir costs $40,000–$75,000 (materials).

Landscaping and Koi Ponds

- Material: EPDM or PVC (0.5–0.75 mm).

- Price: $0.50–$2.00/sq ft (materials), $0.20–$0.50/sq ft (installation).

- Example: A 500 sq ft koi pond costs $250–$1,000 (materials).

Industrial Ponds

- Material: HDPE (1.0–2.0 mm).

- Price: $1.20–$3.50/sq ft (materials), $0.50–$1.50/sq ft (installation).

- Example: A 20,000 sq ft wastewater pond costs $24,000–$70,000 (materials).

Environmental Protection

- Material: Bentonite clay or HDPE (1.5–3.0 mm).

- Price: $0.50–$3.00/sq ft (materials), $0.50–$2.00/sq ft (installation).

- Example: A 1-acre landfill liner (43,560 sq ft) costs $21,780–$130,680 (materials).

4. Step-by-Step Guide to Budgeting for Pond Liners

Step 1: Define Project Requirements

- Application: Identify aquaculture, irrigation, or landscaping needs.

- Specifications: Select thickness (0.5–1.5 mm), tensile strength (10–40 kN/m), and fish-safety certifications.

- Area: Calculate liner size using the formula above. A 10,000 sq ft pond at $0.62/sq ft costs $6,200 in materials.

- Tip: Use online calculators from BPM Geosynthetics for 99% accuracy.

Step 2: Select Liner Material

- HDPE: For large, durable ponds ($0.30–$1.20/sq ft).

- EPDM: For flexible, fish-safe koi ponds ($0.75–$2.00/sq ft).

- PVC: For budget-friendly small ponds ($0.30–$1.50/sq ft).

- Example: A 5,000 sq ft aquaculture pond uses HDPE at $1,500–$6,000.

Step 3: Estimate Material Costs

- Base Price: $0.28–$5.00/sq ft.

- Add-Ons: UV/chemical resistance adds $0.05–$0.15/sq ft.

- Bulk Discounts: Orders >10,000 sq ft save 15–30%.

- Example: A 50,000 sq ft pond at $0.50/sq ft with 20% discount costs $20,000.

Step 4: Factor in Installation Costs

- Site Preparation: $0.10–$0.50/sq ft for excavation.

- Labor: $0.20–$1.50/sq ft; skilled welding for HDPE adds $0.50/sq ft.

- Underlay: $0.25–$0.40/sq ft for geotextile protection.

- Example: A 10,000 sq ft pond with $0.50/sq ft installation costs $5,000.

Step 5: Account for Logistics

- Shipping: $0.05–$0.20/sq ft; international adds 10–20%.

- Storage: Budget $100–$500 for weatherproof storage.

- Example: Shipping 50,000 sq ft at $0.10/sq ft costs $5,000.

Step 6: Plan for Maintenance

- Inspections: $0.01–$0.05/sq ft annually.

- Repairs: Patch kits ($20–$100) avoid $500–$5,000 replacements.

- Example: Annual inspection for 10,000 sq ft at $0.02/sq ft costs $200.

5. Cost Breakdown Example: 10,000 sq ft HDPE Pond Liner for Aquaculture

For a 10,000 sq ft fish pond (50 ft × 200 ft × 4 ft deep) using a 0.5 mm HDPE liner ($0.62–$1.20/sq ft):

- Materials (50%): $6,200–$12,000

- HDPE liner (0.5 mm): $4,500–$8,000

- UV stabilization: $500–$1,000

- Quality control (NSF-61): $1,200–$3,000

- Installation (30%): $2,000–$15,000

- Labor: $1,500–$10,000

- Geotextile underlay: $500–$5,000

- Logistics (15%): $500–$2,000

- Shipping: $400–$1,500

- Storage: $100–$500

- Profit Margin (5%): $400–$1,000

- Total Cost: $9,100–$30,000 ($0.91–$3.00/sq ft)

This liner offers 640 N puncture resistance, <1×10⁻¹¹ cm/s permeability, and a 20–60-year lifespan

6. Cost-Saving Strategies for Pond Liner Projects

Leverage Bulk Purchases

- Benefit: Orders >10,000 sq ft save 15–30%.

- Example: A 2024 Kenyan fish farm saved $3,000 on 20,000 sq ft of HDPE liners (bpmgeosynthetics.com, 2025).

Source Locally

- Benefit: Reduces shipping costs by 10–20%.

- Example: Grekkon Limited in Kenya offers HDPE liners at KSh 240/m², saving 15% on freight

Choose Appropriate Thickness

- Benefit: 0.5 mm liners save 20–30% for small ponds vs. 1.0 mm.

- Example: A 2024 U.S. koi pond saved $2,000 using 0.5 mm EPDM (bpmgeosynthetics.com, 2025).

Use Certified Suppliers

- Benefit: NSF-61 certified liners reduce failure risks by 20%.

- Example: BPM Geosynthetics’ liners avoided $5,000 in repairs for a 2024 project

Optimize Installation

- Benefit: Skilled labor and geotextile underlay prevent 90% of punctures.

- Example: A 2024 Indian project saved $4,000 with professional installation

7. Advanced Considerations for Pond Liner Selection

Site Conditions

- Soil Type: Rocky soils require thicker liners (0.75–1.5 mm); smooth soils suit 0.5 mm.

- Climate: UV-resistant HDPE or EPDM for sunny regions; PVC for covered ponds.

Regulatory Compliance

- Standards: NSF-61 for fish safety, ASTM D6693 for tensile strength.

- Permits: Large ponds (>1,000 sq ft) may require permits ($50–$500).

Long-Term Value

- Lifespan: Certified liners last 20% longer, saving $1,000–$10,000.

- Maintenance: Durable liners reduce cleaning costs by 30%, saving $400–$4,000 annually.

8. Case Studies: Pond Liner Cost Efficiency

Case Study 1: Kenyan Fish Farm

- Project: 20,000 sq ft aquaculture pond using 0.5 mm HDPE.

- Cost: $12,400 (materials, $0.62/sq ft), $6,000 (installation, $0.30/sq ft).

- Savings: Bulk purchase saved 20% ($3,100).

Case Study 2: U.S. Koi Pond

- Project: 500 sq ft koi pond using 0.75 mm EPDM.

- Cost: $500 (materials, $1.00/sq ft), $250 (installation, $0.50/sq ft).

- Savings: DIY installation saved $500.

Case Study 3: Indian Irrigation Pond

- Project: 50,000 sq ft reservoir using 0.75 mm RPE.

- Cost: $40,000 (materials, $0.80/sq ft), $15,000 (installation, $0.30/sq ft).

- Savings: Local sourcing saved $5,000.

9. Conclusion

Pond liner prices, ranging from $0.28 to $5.00 per square foot, depend on material, thickness, size, and installation complexity. With the geomembrane market growing due to water conservation and aquaculture trends, strategic choices like bulk purchasing, local sourcing, and selecting certified suppliers like BPM Geosynthetics or Grekkon Limited can save 15–30% on costs. By defining project needs, choosing the right material, and optimizing installation, stakeholders can achieve 95% leak-proof performance while reducing budgets by $1,000–$50,000. Contact BPM Geosynthetics or local suppliers for tailored quotes and NSF-61 certified liners, ensuring durable, cost-effective water containment.