Share:

Composite geomembrane combines a geomembrane with a geotextile, leveraging the strengths of both materials for a robust and versatile solution in various engineering applications. Representing a pinnacle of geosynthetic innovation, composite geomembranes offer impermeability, strength, and versatility to meet modern engineering demands.

The multilayer of these geomembranes design enables unmatched performance in environmental protection, water management, and infrastructure development. Additionally, their durability and simplified installation contribute to cost-effectiveness, making them a smart investment for projects of all scales.

At BPM Geosynthetics, we provide high-quality composite geomembranes at competitive factory prices, ensuring you receive the best value for your projects. Whether for large infrastructure developments or smaller applications, our composite geomembranes are designed to deliver outstanding results.

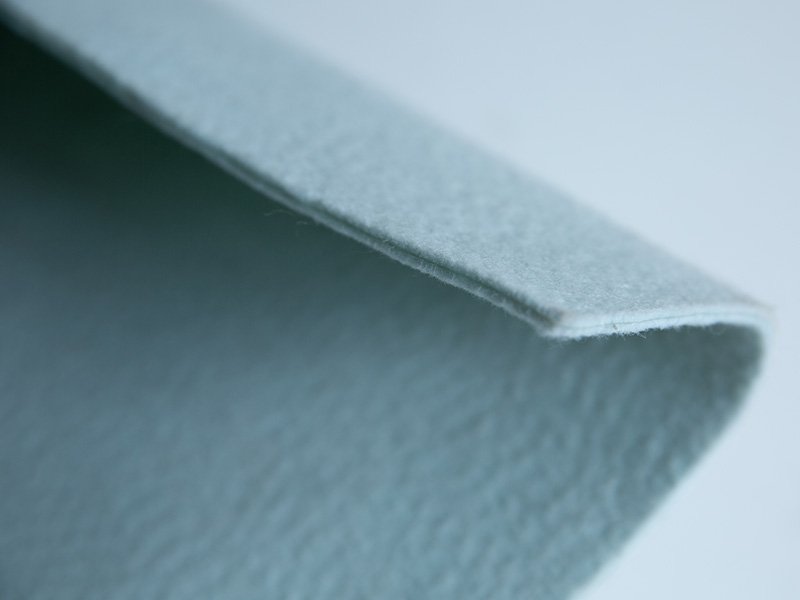

A composite geomembrane is a high-performance geosynthetic material designed to provide superior impermeability and durability in various engineering applications. Unlike traditional geomembranes, which are typically single-layer polymeric sheets, composite geomembranes combine multiple layers—usually a geomembrane bonded with one or more geotextile layers—to enhance functionality. The geomembrane layer, often made from materials like high-density polyethylene (HDPE), low-density polyethylene (LDPE), or polyvinyl chloride (PVC), serves as the primary barrier against liquid or gas seepage. The geotextile layer, typically composed of polyester or polypropylene, adds tensile strength, puncture resistance, and filtration capabilities.

The synergy of these layers makes composite geomembranes uniquely suited for demanding environments. For example, the geotextile protects the geomembrane from mechanical damage during installation, while the geomembrane ensures an impermeable barrier. Configurations of composite geomembranes vary, including one geotextile with one geomembrane, two geotextiles with one geomembrane, or even more complex multilayer designs, depending on project requirements. This versatility allows composite geomembranes to address specific challenges, such as preventing leachate migration in landfills or ensuring water retention in reservoirs.

Composite geomembranes are engineered to meet stringent industry standards, ensuring reliability in applications ranging from waste containment to water management. Their ability to combine the strengths of different materials sets them apart as a preferred choice for projects requiring robust, long-lasting solutions.

| Test Item | Test Properties | Unit | GSO4 | GSO5 | GSO6 | GSO7 | GSO8 |

|---|---|---|---|---|---|---|---|

| Weight | g/m2 | 400 | 500 | 600 | 700 | 800 | |

| Film Thickness | mm | 0.25-0.35 | 0.30-0.50 | ||||

Mechanical Properties | Break Strength | kN/m | 5.0 | 7.5 | 10.0 | 12.0 | 14.0 |

| Break Elongation | % | 30-100 | 30-100 | 30-100 | 30-100 | 30-100 | |

| CBR Burst Strength | KN | 1.1 | 1.5 | 1.9 | 2.2 | 2.5 | |

| Tear Resistance | KN | 0.15 | 0.25 | 0.32 | 0.40 | 0.48 | |

| Peel Strength | N/cm | ≥6 | ≥6 | ≥6 | ≥6 | ≥6 | |

Hydrostatic Pressure | Film Thickness | mm | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 |

| One cloth one film | MPa | 0.4 | 0.5 | 0.6 | 0.8 | 1.0 | |

| Two cloth one film | MPa | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | |

Composite geomembranes are distinguished by a range of features that make them indispensable in geotechnical and environmental engineering. Below are the key characteristics that define their performance:

The geomembrane component of a composite geomembrane is designed to prevent the passage of liquids and gases. Materials like HDPE and PVC offer exceptional resistance to water, chemicals, and environmental contaminants, ensuring a reliable barrier in critical applications.

The geotextile layer significantly boosts the tensile strength of composite geomembranes. This feature allows them to withstand external forces, such as soil pressure or equipment loads, without tearing or deforming.

The combination of geotextile and geomembrane layers provides superior resistance to punctures and tears. This is particularly important during installation, where sharp objects or rough surfaces could compromise the integrity of a standalone geomembrane.

Composite geomembranes are flexible, allowing them to conform to uneven surfaces and complex geometries. This adaptability ensures intimate contact with the underlying soil or substrate, minimizing the risk of leaks or failures.

Many composite geomembranes are formulated with additives to resist ultraviolet (UV) radiation and chemical degradation. This ensures long-term performance in exposed environments or when in contact with aggressive substances like acids or alkalis.

Composite geomembranes can be tailored to specific project needs, with variations in thickness (typically 0.1–1.5 mm for the geomembrane layer), geotextile weight (100–1500 g/m²), and layer arrangements. This customization enhances their suitability for diverse applications.

These features collectively make composite geomembranes a robust and versatile solution, capable of addressing the unique demands of modern engineering projects.

The advantages of composite geomembranes extend beyond their technical specifications, offering practical benefits that enhance project outcomes. Here are the primary advantages:

Composite geomembranes excel at preventing seepage, making them ideal for applications where containment is critical, such as landfills, mining operations, and water storage systems. The multilayer design ensures a reliable barrier, even under high hydraulic pressure.

By combining the protective qualities of geotextiles with the impermeability of geomembranes, composite geomembranes offer exceptional durability. They resist mechanical damage, environmental stressors, and chemical exposure, resulting in a longer service life compared to traditional materials.

Composite geomembranes streamline the installation process by eliminating the need to lay separate geotextile and geomembrane layers. This reduces labor costs and installation time, making projects more efficient without compromising quality.

The geotextile layer improves friction between the composite geomembrane and adjacent materials, such as soil or gravel. This enhanced interface friction prevents slippage on slopes, ensuring stability in applications like landfill liners or dam facings.

Composite geomembranes play a vital role in safeguarding the environment by preventing contaminants from migrating into soil and groundwater. Their use in waste containment and remediation projects supports regulatory compliance and sustainable practices.

From agriculture to industrial waste management, composite geomembranes adapt to a wide range of scenarios. Their ability to meet diverse engineering challenges makes them a go-to solution for professionals worldwide.

These advantages position composite geomembranes as a strategic choice for projects aiming to balance performance, cost, and environmental responsibility.

When evaluating the cost-effectiveness of composite geomembranes, it’s essential to consider both initial investment and long-term savings. While composite geomembranes may have a higher upfront cost compared to single-layer geomembranes or traditional materials like clay or concrete, their overall value becomes evident over time.

Composite geomembranes typically range from $0.50 to $2.00 per square foot, depending on thickness, configuration, and material quality. While this is higher than some alternatives, their durability reduces the need for frequent replacements or repairs. For instance, a well-installed composite geomembrane can last 20–50 years, compared to clay liners, which may crack or erode within a decade.

The integrated design of composite geomembranes simplifies installation, as contractors can deploy a single product rather than multiple layers. This efficiency lowers labor costs and minimizes the risk of installation errors, which can lead to costly rework.

Composite geomembranes require minimal maintenance due to their resistance to UV radiation, chemicals, and mechanical damage. In applications like landfill liners, their ability to prevent leachate leaks reduces the need for expensive environmental remediation, further enhancing cost-effectiveness.

Compared to concrete, which is labor-intensive and prone to cracking, or asphalt, which degrades under chemical exposure, composite geomembranes offer a more economical solution. Their lightweight nature also reduces transportation costs, making them practical for large-scale projects.

In a typical landfill project, using a composite geomembrane can save up to 30% of total costs compared to traditional drainage systems, thanks to its longevity and reduced maintenance needs. This demonstrates that, despite higher initial costs, composite geomembranes deliver significant financial benefits over their lifecycle.

In conclusion, composite geomembranes are highly cost-effective when viewed through the lens of durability, efficiency, and long-term performance. Investing in them ensures reliable containment and protection, ultimately reducing project expenses.

Composite geomembranes are employed across a wide array of industries, addressing critical needs in environmental protection, infrastructure, and resource management. Below are some of the most common applications:

Composite geomembranes are widely used in landfills to prevent leachate from contaminating soil and groundwater. Their impermeability and durability make them ideal for liners and caps, ensuring long-term containment of hazardous waste.

In reservoirs, ponds, and irrigation canals, composite geomembranes prevent water loss due to seepage. They support efficient water management, particularly in arid regions where conservation is paramount.

Heap leach pads and tailings storage facilities rely on composite geomembranes to contain chemicals and prevent environmental contamination. Their chemical resistance and strength withstand the harsh conditions of mining environments.

Composite geomembranes line wastewater lagoons and treatment facilities, preventing harmful substances from infiltrating surrounding ecosystems. Their ability to handle aggressive chemicals ensures reliable performance.

In agriculture, composite geomembranes are used for lining fish ponds, greenhouse reservoirs, and irrigation systems. They maintain optimal moisture levels and protect against root penetration, enhancing productivity.

Composite geomembranes are applied beneath highways and railway tracks to prevent waterlogging and stabilize soil. This improves the longevity of infrastructure and reduces maintenance costs.

For contaminated sites, composite geomembranes create barriers to isolate hazardous materials, facilitating safe remediation. They are critical in projects aimed at restoring polluted land or water bodies.

These applications highlight the versatility of composite geomembranes, making them a cornerstone of modern engineering solutions.

Composite geomembranes typically consist of a geomembrane layer (e.g., HDPE, LDPE, or PVC) bonded with one or more geotextile layers (e.g., polyester or polypropylene). The specific materials depend on the application and performance requirements.

With proper installation and maintenance, composite geomembranes can last 20–50 years or more, depending on environmental conditions and material quality. Factors like UV exposure and chemical contact may influence lifespan.

Yes, composite geomembranes protect the environment by preventing contamination of soil and water. Some are made from recyclable materials, and their durability reduces the need for frequent replacements, supporting sustainability.

Composite geomembranes are designed to perform in a wide range of temperatures and conditions. UV-resistant and flexible formulations ensure reliability in hot, cold, or variable climates.

Installation involves preparing the subgrade, unrolling the composite geomembrane, and seaming the sheets using thermal or chemical methods. Proper anchoring and ballasting prevent wrinkles and ensure intimate contact with the surface.

Composite geomembranes include geotextile layers for added strength and protection, while smooth geomembranes are single-layer polymeric sheets. Composites offer better durability and adaptability for complex projects.

Yes, composite geomembranes can be customized in terms of thickness, geotextile weight, and layer configuration to meet specific project needs, ensuring optimal performance.

BPM Geosynthetics is a global leader and manufacturer of geomembranes engineered specifically for your containment systems. We offer complete range of best quality geomembranes at competitive factory price on fast delivery.

We are at your service in 24 hours/7 days. Any questions or inquiries, please contact us.

When you’re looking for geomembrane or geosynthetics products or services, we are always here repond to your quote as soon as possible.