1.What is the 40 mil HDPE Liner Cost

A 40 mil HDPE liner is a high-density polyethylene geomembrane with a thickness of 40 mils (1 mil = 0.001 inch), equivalent to 1.0 mm. This engineering material is widely used in containment systems due to its impermeability, durability, and resistance to chemicals and UV radiation. HDPE liners are manufactured from premium-grade polyethylene resins, which undergo polymerization processes like slurry, gas-phase, or solution methods to achieve a balance of flexibility and strength. The 40 mil thickness strikes a cost-effective balance between performance and affordability, making it suitable for medium-duty applications such as pond liners, agricultural water storage, and secondary containment in industrial settings. Unlike thicker variants (e.g., 60 mil), 40 mil HDPE liners are lighter and easier to install while still providing robust protection against leaks and environmental degradation.

2.Key Product Characteristics

40 mil HDPE liner cost exhibit a suite of properties that make them ideal for diverse environments:

Chemical Resistance: HDPE is inert to a wide range of chemicals, including acids, alkalis, and industrial effluents, ensuring long-term integrity in corrosive environments.

Mechanical Strength: With high tensile and puncture resistance, 40 mil HDPE withstands moderate mechanical stresses, such as soil movement or equipment contact.

Flexibility and Adaptability: The material conforms to irregular surfaces, facilitating installation in complex geometries like slopes or curved basins.

UV and Environmental Durability: By incorporating carbon black (2–2.5%), HDPE liners resist UV degradation and can endure outdoor exposure for decades.

Waterproofing and Low Permeability: The dense molecular structure of HDPE ensures near-zero permeability, critical for preventing fluid loss or contamination.

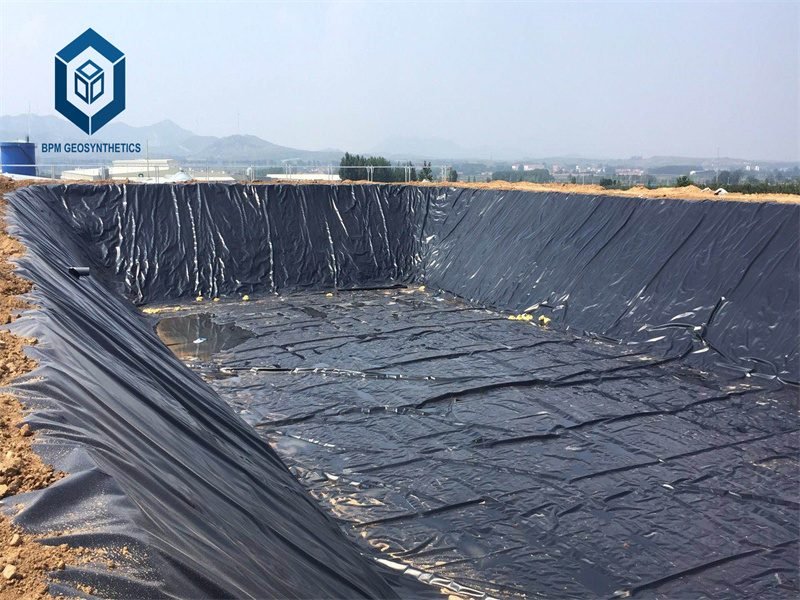

3.Typical Applications–40 mil HDPE Liner Cost

The versatility of 40 mil HDPE liner cost enables their use across multiple sectors:

Water Management: Reservoirs, irrigation canals, and decorative ponds leverage HDPE liners to prevent seepage and conserve water.

Agriculture and Aquaculture: Liners are used in silage pits, fish ponds, and irrigation ponds to maintain water quality and prevent soil contamination.

Industrial Containment: Secondary containment for fuel tanks, chemical storage, and wastewater treatment basins relies on 40 mil HDPE liner cost to isolate hazardous leaks.

Mining and Landfills: While thicker liners (e.g., 60 mil) are preferred for primary landfill liners, 40 mil HDPE serves as caps or temporary containment in mining operations.

Infrastructure Projects: In civil engineering, these liners act as waterproofing layers for tunnels, bridges, and foundations.

4.Price Range and Market Overview

The cost of 40 mil HDPE liner cost varies based on raw material prices, order volume, and manufacturer specifications. According to market data from suppliers like Alibaba:

Bulk Orders: Prices range from $0.30 to $0.69 per square meter for orders of 100 m² or more.

Large-Scale Projects: For orders exceeding 10,000 m², costs can reach $1.29–1.31 per square meter, often including technical support or installation guidance.

4.1.Factors influencing pricing include:

Raw Material Fluctuations: HDPE prices depend on ethylene costs and supply chain dynamics.

Customization: Textured surfaces (e.g., double-sided for slope stability) or additives (e.g., UV inhibitors) may increase costs.

Geographic Region: Manufacturers in Asia, particularly China, offer competitive rates due to lower production costs, whereas North American or European suppliers charge premium prices for compliance with strict regulatory standards.

5.Comparison with International Counterparts–40 mil HDPE Liner

When comparing 40 mil HDPE liners cost from global manufacturers, key distinctions emerge:

Production Technology: Western companies (e.g., in the U.S. or EU) often employ advanced processes like Unipol PE (gas-phase) or Hostalen (slurry) to produce bimodal HDPE with superior consistency and mechanical properties. In contrast, Chinese manufacturers like BPM typically use cost-effective slurry or gas-phase methods, prioritizing economies of scale.

Quality Standards: International products adhere to stringent certifications (e.g., ASTM GRI GM13, ISO 9080), ensuring performance in extreme conditions. Chinese liners meet basic ASTM standards but may lag in long-term durability testing.

Customization and Innovation: Western manufacturers excel in tailored solutions (e.g., site-specific welding techniques), while Chinese brands focus on providing affordable, versatile products for broad applications.

Regulatory Compliance: In regions like the EU and North America, liners must satisfy environmental regulations (e.g., for landfill liners), driving higher costs. Chinese products are increasingly aligning with these benchmarks but remain more affordable.

6.Advantages of BPM Brand Products–40 mil HDPE Liner Cost

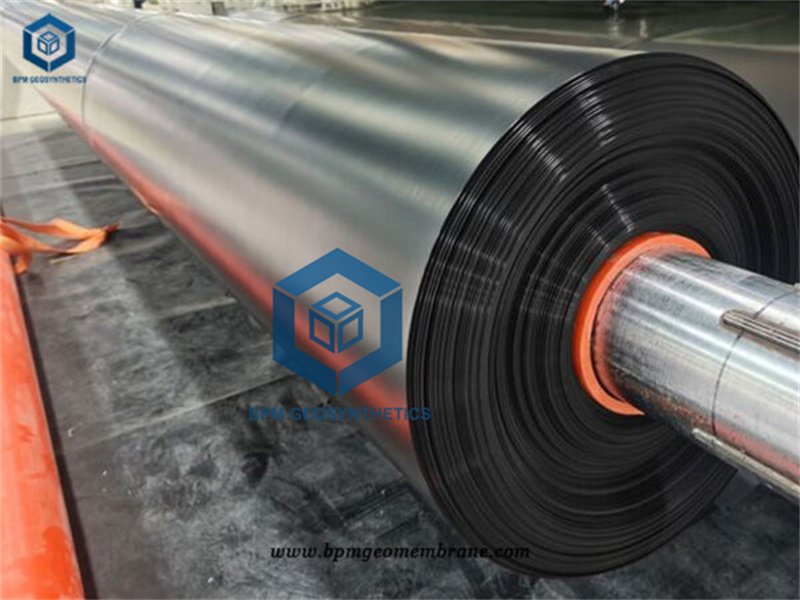

BPM Geosynthetics, a prominent manufacturer from China, stands out through the following strengths:

Cost-Effectiveness: By optimizing production scales, BPM offers 40 mil HDPE liners at competitive prices (as low as $0.30/m² for bulk orders), making them accessible for budget-conscious projects.

Comprehensive Product Range: The brand provides liners in thicknesses from 0.2 mm to 3.0 mm, widths of 1–8 meters, and multiple textures (smooth or double-textured) to suit varied needs.

Quality Assurance: BPM liners comply with international standards like ASTM GRI GM13 and hold certifications (e.g., ISO, SASO), guaranteeing chemical resistance, tensile strength, and UV stability.

Technical and After-Sales Support: The company offers end-to-end services, including installation guidance, welding training, and on-site troubleshooting, reducing project risks.

Global Competitiveness: BPM products are exported to markets in North America, Europe, and Africa, rivaling international brands in performance and affordability

7.Conclusion

The 40 mil HDPE liner cost is a versatile and economical solution for containment applications in water management, agriculture, and industry. Its pricing, influenced by raw material costs and order volume, remains highly competitive, with Chinese suppliers like BPM offering cost-effective options without compromising baseline quality. While international manufacturers lead in advanced production technologies and tailored innovations, brands such as BPM have narrowed the gap through certifications and comprehensive customer support. For projects requiring a balance between performance and affordability, 40 mil HDPE liners represent a prudent investment. As environmental regulations evolve, selecting suppliers that adhere to global standards will be crucial for ensuring long-term reliability and environmental safety.

As the largest geomembrane liner companies in China, BPM has more than 160 professional staff and 36,000 square meters géomembrane manufacturing factory equipped with state of the art geomembrane production lines. BPM geomembrane factory is certificated by ISO9001, ISO14001, and OHSAS18001. All BPM geomembranes have passed the certificates of the TUV, Soncap, SASO, BV and the test of SGS and Intertek etc. Product innovation, quality assurance and customer satisfaction are our long term commitment to our worldwide customers. Hope to be your partner.

BPM had provided many types of effective and states of the art geomembranes and other geosythetics to over 36 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia etc.