High-Density Polyethylene (HDPE) liners are one of the most versatile and widely used materials in various industries, including construction, agriculture, mining, waste management, and environmental protection. Known for their durability, chemical resistance, and flexibility, HDPE liners are an excellent choice for applications such as pond liners, landfill liners, reservoir covers, and more. If you’re in the market for an HDPE liner Price, it’s essential to understand the key factors that influence their performance, HDPE Liner Price, and suitability for your specific needs. This ultimate guide will walk you through everything you need to know about HDPE Liner Price for sale, helping you make an informed decision.

1. What is HDPE Liner?

HDPE liners are geomembranes made from high-density polyethylene, a thermoplastic polymer known for its strength, durability, and resistance to chemicals, UV radiation, and extreme temperatures. These liners are manufactured in sheets of varying thicknesses and are used to create impermeable barriers in a wide range of applications. HDPE liners are particularly popular because they are:

1.1 HDPE Liner Price – Durable:

Resistant to punctures, tears, and environmental stressors.

1.2 HDPE Liner Price – Flexible:

Can conform to uneven surfaces and withstand ground movement.

1.3 HDPE Liner Price – Chemically Resistant:

Impervious to most acids, alkalis, and organic solvents.

1.4 HDPE Liner Price – Cost Effective:

Offers a long lifespan with minimal maintenance, reducing long-term costs.

2. Applications of HDPE Liners Price.

HDPE liners Price are used in a variety of industries and applications, including:

Pond and Lake Liners: Used to create watertight barriers in decorative ponds, fish farms, and irrigation reservoirs.

2.1 Landfill Liners:

Prevent leachate from contaminating groundwater in waste disposal sites.

2.2 Mining:

Line tailings ponds and heap leach pads to contain harmful chemicals.

2.3 Agriculture:

Used in irrigation canals, silage pits, and manure storage.

2.4 Industrial:

Line secondary containment areas for chemical storage tanks and wastewater treatment facilities.

2.5 Environmental Protection:

Used in stormwater management systems and erosion control projects.

3 Key Factors to Consider When Buying an HDPE Liner Price

When shopping for an HDPE liner Price, several factors will influence your choice. Understanding these factors will help you select the right liner for your project and ensure optimal performance.

3.1 HDPE Liner Price – Thickness

The thickness of an HDPE Liner Price is one of the most critical factors to consider. Thicker liners offer greater durability and resistance to punctures but may be more expensive and less flexible. Common thicknesses range from 0.2 mm to 3.0 mm.

0.2 mm to 1.0 mm: Suitable for lightweight applications such as decorative ponds or temporary containment.

1.0 mm to 2.0 mm: Ideal for medium-duty applications like agricultural ponds or small reservoirs.

2.0 mm to 3.0 mm: Best for heavy-duty applications such as landfills, mining, or industrial containment.

Choose a thickness that matches the demands of your project, considering factors like the type of material being contained, the weight of the load, and the potential for punctures.

3.2 HDPE Liner Price – Size and Dimensions

HDPE liners are available in rolls of varying widths and lengths. The size you need will depend on the area you need to cover. Most manufacturers offer custom sizes to fit specific project requirements.

Width: Standard widths range from 5 to 12 meters, but custom widths are available.

Length: Rolls can be manufactured in lengths of up to 100 meters or more.

Ensure you measure the area accurately and account for overlaps (typically 6 to 12 inches) when calculating the required liner size.

3.3 HDPE Liner Price – Material Quality

Not all HDPE Liner are created equal. The quality of the raw materials used in manufacturing can significantly impact the liner’s performance and lifespan. Look for liners made from virgin HDPE resin, as recycled materials may compromise durability and chemical resistance.

Virgin HDPE: Offers superior strength, flexibility, and resistance to environmental stressors.

UV Stabilization: UV-stabilized HDPE liners are essential for outdoor applications to prevent degradation from sunlight exposure.

3.4. HDPE Liner Price – Chemical Resistance

HDPE Liner are known for their excellent chemical resistance, but it’s essential to ensure the liner is compatible with the specific chemicals it will be exposed to. For example:

Acids and Alkalis: HDPE Liner Price are resistant to most acids and alkalis, making them suitable for industrial and mining applications.

Organic Solvents: While HDPE Liner Price is generally resistant to organic solvents, prolonged exposure to certain chemicals may require a specialized liner.

Consult the manufacturer’s chemical resistance chart to confirm compatibility with your application.

3.5 Installation Requirements

Proper installation is crucial for the performance of an HDPE Liner Consider the following factors:

Subgrade Preparation: The surface beneath the liner must be smooth, free of sharp objects, and properly compacted to prevent punctures and ensure a tight fit.

Seaming Methods: HDPE liners are typically joined using thermal fusion (heat welding) or extrusion welding. Ensure you have access to the necessary equipment and expertise.

Anchoring: The liner must be securely anchored at the edges to prevent movement or uplift caused by wind or water pressure.

3.6 Environmental Factors

Environmental conditions such as temperature, UV exposure, and soil composition can affect the performance of an HDPE Liner.

Temperature: HDPE Liner Price can withstand a wide range of temperatures, but extreme heat or cold may require specialized formulations.

UV Exposure: For outdoor applications, choose a UV-stabilized liner to prevent degradation.

Soil Composition: In areas with rocky or abrasive soil, consider using a geotextile underlay to protect the liner from punctures.

3.7 HDPE Liner Price

The HDPE Liner depends on factors such as thickness, size, material quality, and customization. While it may be tempting to opt for a cheaper option, investing in a high-quality liner can save you money in the long run by reducing maintenance and replacement costs.

Price Range: HDPE Liner Price typically cost between 0.50mm and3.00mm per square meter, depending on the specifications.

Customization: Custom sizes, thicknesses, and additives (e.g., UV stabilizers) may increase the cost.

4 Advantages of HDPE Liners

HDPE Liner Price offer numerous advantages over other types of geomembranes, including:

Durability: HDPE liners can last for decades with minimal maintenance, even in harsh environments.

Flexibility: Their ability to conform to uneven surfaces makes them suitable for a wide range of applications.

Chemical Resistance: HDPE liners are resistant to most chemicals, making them ideal for industrial and hazardous waste containment.

Cost-Effectiveness: Their long lifespan and low maintenance requirements make them a cost-effective solution.

Environmental Safety: HDPE Liner Price are non-toxic and safe for use in applications involving potable water or food storage.

5 HDPE Liner Price – Disadvantages of HDPE Liners

While HDPE liners offer many benefits, they also have some limitations:

Limited Flexibility in Cold Weather: HDPE liners can become less flexible in extremely cold temperatures, making installation more challenging.

Susceptibility to Stress Cracking: Prolonged exposure to certain chemicals or mechanical stress can cause stress cracking.

Installation Complexity: Proper installation requires specialized equipment and expertise, which can increase HDPE Liner Price.

6 HDPE Liner Price – Installation Tips for HDPE Liners

Proper installation is key to maximizing the performance and lifespan of an HDPE liner. Follow these tips:

Prepare the Subgrade: Remove sharp objects, rocks, and debris, and compact the soil to create a smooth, stable surface.

Use a Geotextile Underlay: In areas with rocky or abrasive soil, a geotextile underlay can protect the liner from punctures.

Seam Carefully: Use thermal fusion or extrusion welding to create strong, leak-proof seams.

Anchor Securely: Anchor the liner at the edges using trenches, anchor bolts, or other methods to prevent movement.

Inspect Regularly: After installation, inspect the liner for damage or leaks and address any issues promptly.

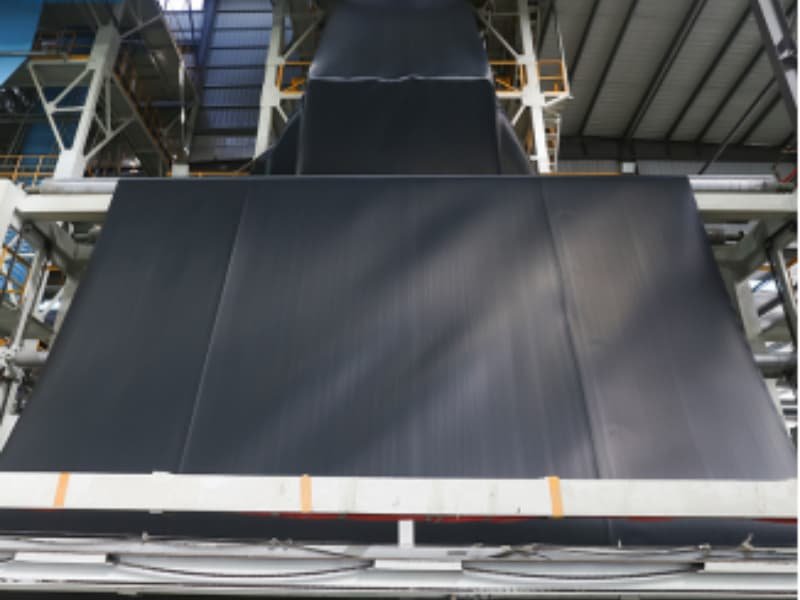

As a HDPE Liner export manufacturer for 20 years, our factory has 3 lines of smooth HDPE Geomembrane equipment and one line of rough surface HDPE Geomembrane equipment. We can produce HDPE Geomembranes with widths from 2 meters to 10 meters. We can produce HDPE Liner thicknesses from 0.2mm to 3mm. Because our HDPE Geomembranes need to be shipped in containers and shipped to customers, most customers ask us to produce widths of 5.8mm or 7 meters or 8 meters. If you have other widths, we can also produce them. If you need a width of 3 meters, it may produce some waste of raw materials. The price of a 3-meter wide HDPE Liner may be higher than the price of a normal width (5.8m to 10m) HDPE Geomembrane.

HDPE Liner Price are a versatile, durable, and cost-effective solution for a wide range of applications. Whether you’re lining a pond, landfill, or industrial containment area, choosing the right HDPE liner is essential for ensuring long-term performance and reliability. By considering factors such as thickness, size, material quality, chemical resistance, and installation requirements, you can select the perfect liner for your project.

When shopping for HDPE Liner for sale, take the time to research suppliers, compare options, and consult with experts if needed. With the right liner and proper installation, you can create a reliable, long-lasting barrier that meets your needs and stands the test of time.